Your single source for simple to complex catheter mandrels straight, curved, and grooved

About Mountain manufacturing technologies..

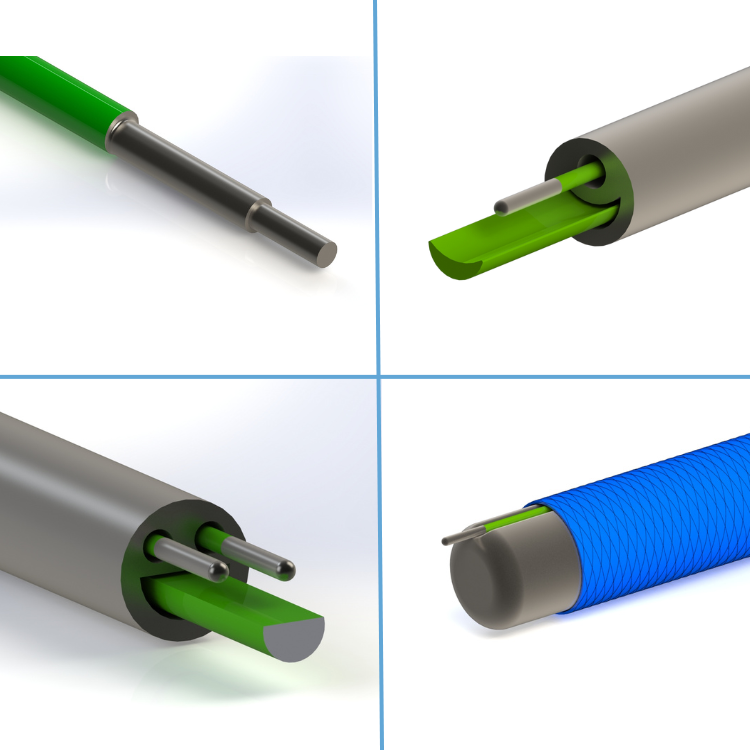

Mountain Manufacturing Technologies takes pride in supporting catheter development by providing top-notch manufacturing services to customers ranging from start-ups to large OEMs. We are your technical design and manufacturing partner for complex mandrels utilizing various stainless steel alloys and nitinol. Our expertise includes handling complex geometries, multi-lumen profiles, D-shaped mandrels, cylindrical step mandrels, and hollow-core mandrels.

Catheter Mandrels

Engineering of mandrel features can dramatically improve catheter assembly output and significantly reduce scrap by enhancing the precision of the catheter manufacturing process. Below are categories of common mandrel geometrics that assist in assembly manufacturing.

Design Features Include:

ECCENTRIC

FLAT

GROOVED

HOLLOW CORE

NOTCHED

SHAPED

Materials Include:

STAINLESS STEEL TYPES

- 304 Series

- 400 Series

- 17-4, 17-7

TOOL SERIES

- A2

- M2

- O1

Nitinol

PTFE Coated

Heat Set Tooling:

Mountain’s vertically integrated facility specializes in developing and manufacturing heat-set tooling to ensure smooth navigation through the body’s complex anatomy using complex catheter systems. These advanced tools can accelerate production and offer a range of heat-setting options, enabling the creation of catheters with optimal structural integrity and flexibility to meet your end product's performance requirements.

HEAT SET TOOLING

PRECISE & CONSISTENT SHAPING

ACCELERATED PRODUCTION

HEAT SETTING OPTIONS

Become a connection on LinkedIn.